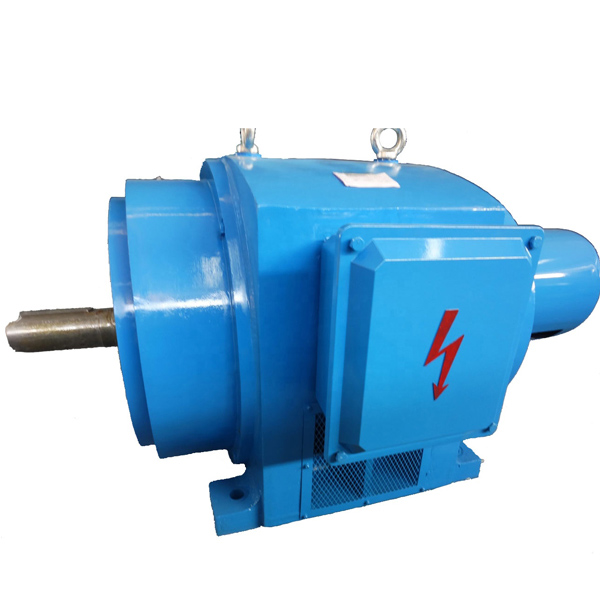

JR Wound Rotor Slip Ring AC Motor

JR Wound Rotor Slip Ring AC Motor Description

The JR series motor is a protective winding type rotor three-phase asynchronous motor with cooling method IC01 and continuous working system (S1). This series of motors can provide a large starting torque at a small starting current and can adjust the speed within a certain range.

JR series motors comply with the ministerial quasi-JB564-64 technical conditions

JR Wound Rotor Slip Ring AC Motor Feature

The JR winding slip ring motor casing is a cast iron casing or a steel plate welded casing with high structural strength and good mechanical properties. The motor shaft extension end and the non-bearing end have an inlet and outlet air outlet, and the motor slip ring is located at the non-bearing end. The series of motors have simple structure, convenient installation, convenient maintenance, large starting torque and safe and reliable operation. JR winding slip ring motors can drive a variety of different machines, such as fans, compressors, pumps, crushers, ball mills, winches, hoists, transport machinery and other equipment, as well as mines, machinery, power plants and Used as prime mover in various industrial and mining enterprises.

The JR series motor is a wound rotor three-phase asynchronous motor. This series of motors meets the technical standard conditions. It can drive a variety of different machines, such as fans, compressors, pumps, crushers, ball mills, cutting machines, transport machinery and other equipment. It is used as a prime mover in the machinery industry, power plants and various industrial and mining enterprises. The rating of the JR winding slip ring motor is based on the continuous working system (S1). The frequency is 50HZ, the rated voltage is 220V/380V, 380V, 415V, 3000V, 6000V, which can be designed to 3300V/10000V according to the needs of users.

The protection of this series of motors is IP23; the cooling method is IC01; the structure and installation method of the motor is generally IMB3, and it can also be designed as vertical installation according to customer requirements.

The ratio of the maximum torque to the rated torque of the JR winding slip ring motor at rated voltage is not less than 1.8.

The JR winding slip ring motor must be connected to the starting varistor in the rotor circuit at the start. It is not permissible to short-circuit the rotor windings directly.

JR Wound Rotor Slip Ring AC Motor Principle of Work

Ambient temperature: -15°C–40°C

Altitude: not exceed 1000m

Rated voltage: 380V, 660V, 3300V, 6000V, 6300V, 6600V, 10000V

Rated Power: 50Hz

working system: S

Protection grade: IP23

Rated temperature: 80

Installation Type:F

The basic structure: B3;

Installation Type: B3

JR Wound Rotor Slip Ring AC Motor Advantages

* Totally enclosed fan cooling

* Conforms to the IEC standard

* High efficiency

* Energy saving

* High starting torque

* Low noise

* Slight vibration

* Light weight

* Reliable and convenient operation

* Easy maintenance

Comparison Of Different series High Voltage Motors

| No. | Squirrel-cage motor | Y JS | YKK | YKS | Y2, Y3 |

| Slip ring motor | YR JR JR2 | YRKK | YRKS | YR2, YR3 | |

| 1 | Structure | Box-type construction, made up of steel plates welded with each other | Compact struction | ||

| 2 | Cooling method | IC01 or (IC11, IC21, IC31) | IC611 or IC616 | IC81W | IC411 |

| 3 | Natural ventilation, with top mounted protection cover | With top mounted air-air cooler | With top mounted air-water cooler | ||

| 4 | Protection type | IP23 | IP44 or IP54 | IP44 or IP54 | IP54 |

| 5 | Insulation | F | |||

| 6 | Mounting arrangement | IMB3 | |||

| 7 | Voltage available | 380 v, 2400 v, 3kv, 3.3kv; 4160 v, 5500V 6kv, 6.6kv; 10kv, 11kv | |||

| 8 | Frequency available | 50Hz , 60Hz | |||

JR Wound Rotor Slip Ring AC Motor Technical Parameter

| JR Series 3 Phase Slip Ring Induction Motor | ||||||||||||

| Type | Rated | Rated | Rated | Stator | Effi | Power | Tmax/Tn | Rotor | Rotor | Rotor | Cooling | Weight |

| power | voltage | Speed | current | -ciency | factor | Voltage | Current | Flywheel | air | Wt. | ||

| torque | ||||||||||||

| (kW) | (V) | (r/min) | (A) | (η%) | (cos ϕ) | (time) | (V) | (A) | (N·m2) | (m3/S) | (Kg) | |

| JR114-4 | 115 | 380 | 1450 | 212 | 91 | 0.904 | 2 | 173 | 433 | 160 | 0.5 | 1035 |

| JR115-4 | 135 | 380 | 1460 | 246 | 92.1 | 0.904 | 2.33 | 210 | 408 | 180 | 0.55 | 1130 |

| JR116-4 | 155 | 380 | 1460 | 278 | 92.7 | 0.913 | 2.28 | 238 | 412 | 200 | 0.6 | 1200 |

| JR117-4 | 180 | 380 | 1460 | 321 | 93.1 | 0.911 | 2.45 | 275 | 409 | 220 | 0.65 | 1270 |

| JR126-4 | 225 | 380 | 1470 | 405 | 93.1 | 0.907 | 2.2 | 291 | 488 | 370 | 0.9 | 1660 |

| JR127-4 | 260 | 380 | 1472 | 461 | 93 | 0.92 | 2.18 | 334 | 493 | 400 | 1 | 1760 |

| JR128-4 | 300 | 380 | 1475 | 530 | 93.9 | 0.917 | 2.37 | 390 | 482 | 440 | 1.1 | 1890 |

| JR136-4 | 220 | 6000 | 1475 | 26 | 91.7 | 0.894 | 1.97 | 307 | 457 | 590 | 1.3 | 2110 |

| JR137-4 | 260 | 6000 | 1480 | 30.3 | 92.3 | 0.897 | 1.92 | 346 | 481 | 630 | 1.4 | 2210 |

| JR138-4 | 300 | 6000 | 1478 | 35 | 92.4 | 0.9 | 1.96 | 398 | 483 | 710 | 1.5 | 2320 |

| JR147-4 | 360 | 6000 | 1479 | 41 | 93.1 | 0.904 | 2.68 | 558 | 406 | 850 | 1.2 | 3000 |

| JR148-4 | 440 | 6000 | 1475 | 49 | 93.44 | 0.92 | 2.68 | 634 | 410 | 1000 | 1.4 | 3300 |

| JR1410-4 | 500 | 6000 | 1482 | 55.5 | 94.1 | 0.92 | 2.44 | 717 | 420 | 1200 | 1.5 | 3600 |

| JR158-4 | 680 | 6000 | 1480 | 77.8 | 93.8 | 0.87 | 2.7 | 722 | 586 | 1700 | 1.7 | 4500 |

| JR1510-4 | 850 | 6000 | 1483 | 95.9 | 94.3 | 0.904 | 2.5 | 803 | 657 | 2100 | 1.9 | 4700 |

| JR1512-4 | 1050 | 6000 | 1480 | 118 | 94.4 | 0.9 | 2.3 | 1035 | 630 | 2500 | 2.2 | 5450 |

| JR115-6 | 75 | 380 | 965 | 142 | 90.3 | 0.89 | 1.98 | 127 | 382 | 210 | 0.45 | 1025 |

| JR116-6 | 95 | 380 | 970 | 177 | 91.74 | 0.891 | 2.33 | 162 | 371 | 240 | 0.5 | 1115 |

| JR117-6 | 115 | 380 | 973 | 213 | 92.1 | 0.893 | 2.32 | 191 | 381 | 260 | 0.55 | 1170 |

| JR125-6 | 130 | 380 | 976 | 245 | 91.4 | 0.882 | 1.87 | 187 | 445 | 400 | 0.67 | 1450 |

| JR126-6 | 155 | 380 | 977 | 294 | 91.1 | 0.873 | 1.85 | 219 | 455 | 440 | 0.75 | 1530 |

| JR127-6 | 185 | 380 | 977 | 334 | 92.8 | 0.907 | 2.27 | 366 | 319 | 490 | 0.8 | 1560 |

| JR128-6 | 215 | 380 | 979 | 385 | 93.3 | 0.908 | 2.44 | 424 | 317 | 540 | 0.9 | 1630 |

| JR136-6 | 240 | 380 | 977 | 436 | 93 | 0.905 | 1.85 | 407 | 376 | 760 | 1.1 | 1970 |

| JR137-6 | 280 | 380 | 981 | 507 | 93.14 | 0.907 | 2.15 | 490 | 360 | 840 | 1.2 | 2030 |

| JR148-6 | 310 | 6000 | 983 | 36.8 | 91.99 | 0.88 | 2.2 | 505 | 374 | 1650 | 1.1 | 3360 |

| JR1410-6 | 380 | 6000 | 983 | 44.7 | 92.5 | 0.88 | 2.1 | 590 | 391 | 1850 | 1.1 | 3630 |

| JR157-6 | 460 | 6000 | 985 | 54 | 92 | 0.87 | 2 | 568 | 517 | 2300 | 1.4 | 3700 |

| JR158-6 | 550 | 6000 | 985 | 64 | 92.5 | 0.87 | 2 | 618 | 570 | 2600 | 1.6 | 4000 |

| JR1510-6 | 650 | 6000 | 985 | 75 | 93 | 0.87 | 2.1 | 741 | 560 | 3300 | 1.8 | 4500 |

| JR1512-6 | 780 | 6000 | 985 | 89 | 93.5 | 0.88 | 2.2 | 862 | 570 | 4000 | 2 | 4750 |

| JR115-8 | 60 | 380 | 720 | 120 | 89.38 | 0.846 | 2.59 | 172 | 230 | 250 | 0.38 | 980 |

| JR116-8 | 70 | 380 | 723 | 137 | 90.27 | 0.856 | 2.57 | 199 | 225 | 280 | 0.41 | 1060 |

| JR117-8 | 80 | 380 | 723 | 154 | 90.96 | 0.869 | 2.45 | 222 | 230 | 310 | 0.45 | 1135 |

| JR125-8 | 95 | 380 | 725 | 183 | 90.55 | 0.867 | 1.89 | 213 | 292 | 450 | 0.6 | 1380 |

| JR126-8 | 110 | 380 | 726 | 212 | 90.75 | 0.866 | 1.84 | 243 | 294 | 510 | 0.65 | 1550 |

| JR127-8 | 130 | 380 | 728 | 242 | 92.15 | 0.88 | 2.04 | 256 | 324 | 570 | 0.7 | 1500 |

| JR128-8 | 155 | 380 | 732 | 291 | 92.54 | 0.875 | 2.3 | 309 | 316 | 640 | 0.76 | 1600 |

| JR136-8 | 180 | 380 | 735 | 345 | 92.25 | 0.858 | 2 | 354 | 323 | 770 | 0.88 | 1850 |

| JR137-8 | 210 | 380 | 734 | 400 | 93 | 0.86 | 1.84 | 394 | 341 | 850 | 0.95 | 1940 |

| JR138-8 | 245 | 380 | 734 | 453 | 93.1 | 0.86 | 1.8 | 425 | 365 | 850 | 0.95 | 2060 |

| JR147-8 | 200 | 6000 | 738 | 25.7 | 91.6 | 0.818 | 2.5 | 406 | 299 | 1500 | 0.85 | 3090 |

| JR148-8 | 240 | 6000 | 738 | 30.6 | 92 | 0.821 | 2.43 | 457 | 319 | 1650 | 0.85 | 3300 |

| JR1410-8 | 280 | 6000 | 740 | 35.7 | 92.3 | 0.818 | 2.55 | 550 | 309 | 1850 | 0.85 | 3600 |

| JR157-8 | 320 | 6000 | 739 | 39 | 92.5 | 0.86 | 2.2 | 509 | 395 | 2300 | 1.2 | 3700 |

| JR158-8 | 380 | 6000 | 738 | 45.6 | 93 | 0.86 | 2.22 | 547 | 436 | 2600 | 1.3 | 4000 |

| JR1510-8 | 475 | 6000 | 738 | 56 | 93.28 | 0.856 | 2.031 | 641 | 468 | 3300 | 1.5 | 4500 |

| JR1512-8 | 570 | 6000 | 738 | 66.9 | 93.72 | 0.86 | 1.981 | 698 | 514 | 4000 | 1.7 | 4750 |

| JR115-10 | 45 | 380 | 577 | 97 | 88 | 0.8 | 2.21 | 117 | 252 | 260 | 0.3 | 950 |

| JR116-10 | 55 | 380 | 577 | 116 | 89 | 0.805 | 2.17 | 140 | 256 | 280 | 0.33 | 1040 |

| JR117-10 | 65 | 380 | 577 | 135 | 89 | 0.81 | 2.16 | 159 | 263 | 310 | 0.36 | 1110 |

| JR125-10 | 80 | 380 | 574 | 164 | 90.15 | 0.817 | 1.96 | 168 | 309 | 460 | 0.5 | 1350 |

| JR126-10 | 95 | 380 | 573 | 193 | 90.44 | 0.825 | 1.83 | 188 | 326 | 520 | 0.5 | 1440 |

| JR127-10 | 115 | 380 | 575 | 233 | 90.9 | 0.82 | 1.92 | 225 | 328 | 580 | 0.55 | 1590 |

| JR128-10 | 130 | 380 | 575 | 261 | 91.14 | 0.826 | 1.83 | 251 | 333 | 650 | 0.6 | 1720 |

| JR137-10 | 155 | 380 | 583 | 307 | 91.45 | 0.854 | 2 | 354 | 280 | 930 | 0.75 | 1920 |

| JR138-10 | 180 | 380 | 583 | 346 | 91.6 | 0.86 | 1.8 | 387 | 300 | 1050 | 0.81 | 2090 |

| JR1410-10 | 200 | 6000 | 590 | 27 | 90.5 | 0.8 | 2.7 | 511 | 248 | 2100 | 0.9 | 3300 |

| JR157-10 | 260 | 6000 | 588 | 33.5 | 91.2 | 0.81 | 2.1 | 412 | 406 | 3000 | 1.1 | 3700 |

| JR158-10 | 310 | 6000 | 585 | 39.5 | 91.7 | 0.81 | 2 | 442 | 454 | 3400 | 1.2 | 4000 |

| JR1510-10 | 400 | 6000 | 585 | 50.3 | 92 | 0.82 | 2.2 | 554 | 467 | 4200 | 1.4 | 4500 |

| JR1512-10 | 480 | 6000 | 585 | 60 | 92.9 | 0.81 | 2.3 | 602 | 512 | 5100 | 1.6 | 4750 |

| JR1510-12 | 280 | 6000 | 490 | 38 | 91.4 | 0.77 | 2.2 | 478 | 380 | 4200 | 1.2 | 4500 |

| JR1512-12 | 330 | 6000 | 490 | 44 | 91.7 | 0.78 | 2.1 | 515 | 413 | 5100 | 1.3 | 4750 |