The faults of high-voltage explosion-proof motors can be divided into electrical faults and machine faults. The important faults in the machine are vibration, bearing overheating, rotor sweeping, abnormal running sound, etc.; in the electrical field, if the motor winding is grounded, short-circuited, open circuit, bad contact, squirrel cage broken and other faults.

The insulation failure of high-voltage explosion-proof motor windings is affected by the performance of the insulating material, the control of the manufacturing process, the operating environment and the comprehensive factors such as electricity, heat, and chemistry.

1. Electrochemical breakdown

The two faulty motors in the gas-making workshop of a factory have collapsed and checked. One stator winding has three insulation breakdowns, and one has insulation breakdown everywhere. All are pitting damage to the insulation, causing “creepage”, showing burn marks, gaps, and electrical conductivity. channel, and the fault points are all present at the end of the motor air inlet and tend to move toward the dead center. In this regard, we explained the reasons from the aspects of motor layout, operating environment, operation method, etc., and initially determined that the motor was due to unreasonable selection and the bad operating environment caused electrochemical breakdown.

The electrochemical breakdown caused by the harsh operating environment is an important cause of insulation damage. The acid and alkaline corrosive gases existing in the air will corrode the surface of the insulating material for a long time. When the air humidity is high, the performance of the insulating material will be improved, and the inorganic insulating material will easily cause damage under the comprehensive action of electricity, heat, chemistry and other factors. ***Incurs breakdown.

2. Frequent startup

The frequent starting of high-voltage explosion-proof motors directly affects their service life. This is because the motor secretly withstands the blow of a large current when starting, and the windings must withstand the superimposed effect of the motor and thermal stress. Because the shrinkage coefficient of the winding insulation material is different from that of the copper conductor, a large frying stress is formed between the insulation material and the conductor during startup, the firmness between the conductor and the insulation material will be destroyed, and the insulation will be delaminated or torn. Insulation breakdown occurs.

When the squirrel-cage asynchronous motor is started frequently, it is easy to cause the squirrel cage to break, especially the load-starting motor, the probability of failure is higher.

3. Disadvantages of embedded wire

When the wire is embedded, the end of the binding causes the end insulation collapse damage, which is another important factor that causes the damage of the high-voltage motor winding. For the parts touched by the end ring, the outer insulation is different and the concave grooves are extruded horizontally, so that a part of the hardened insulating material is extruded to the edge of the binding contact surface, and after the whole is cured, the The insulation of some parts is significantly thinned and the insulation strength is low.

4. The insulation quality of the hand bag at the end is poor

There are many cases where the poor insulation quality of the handbag at the end constitutes an interphase or relative short circuit at the end. The insulating cladding of the handbag is not tight, and there are gaps on the outside. When the ambient humidity is high, the insulating performance of the winding is significantly reduced until the surface of the insulating material is dew. The discharge mechanism is that a water film is first formed on the surface of the insulation. Under the action of the electric field, the water film is ionized and causes the ions to move and collect along the surface, resulting in uneven distribution of the electric field, and at the same time reducing the external discharge voltage. This kind of discharge along the surface is actually a phenomenon of gas dielectric discharge, and its voltage is much lower than the breakdown voltage that exists in many gases or solids, and the “creepage” interval of the occasional extension surface can reach tens of centimeters. Creeping discharge can cause continuous breakdown flashover between high potentials, that is, interphase short-circuit accident.

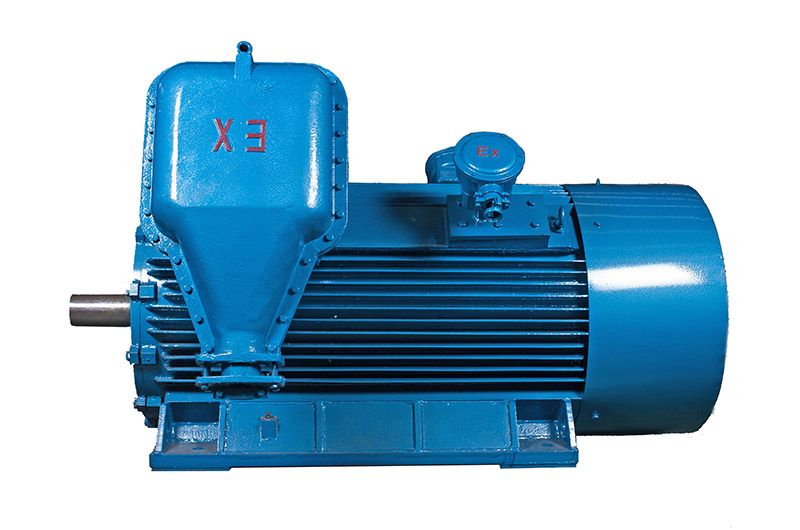

The operating environment of explosion-proof motors is harsh, the working conditions are complex, there are many uncertain factors, and the hidden dangers are relatively large. Correctly selecting the appropriate explosion-proof grade explosion-proof motor is the premise of everything. Buying brand explosion-proof motors from regular channels will have more guarantees. Henan Province Guanwei Electromechanical Technology Co., Ltd. is based on Henan and has become the core distributor of Wolong Electric Nanyang Explosion-proof Group Co., Ltd. The company focuses on high-quality brand motor sales and technical services, and has a team of high-quality professionals engaged in trade Over the years, we have accumulated many advantageous channels, and strive to provide high-quality products and high-quality services for domestic and foreign customers!

Post time: 2022-02-14